Description

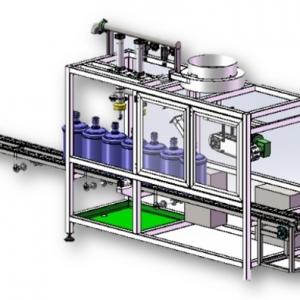

Automatic 5 gallon rotary leakage test machine

In order to meet demand, empty plastic 5 gallon containers are manufactured in high volumes. When containers are filled and shipped, there will always be some defects that will cause leaks. With leak detection equipment in the production line, plastic bottles are tested as they move along the line and rejected if they are defective.

Tests conducted on empty containers can identify leaks before bottles reach the end of the production line, significantly reducing the possibility of a bottle recall.

The products can be used for on-line inspection and are available in options for rang of size and capacity of empty plastic bottles.

Machine description:

This equipment is comprised of the frame, the frame shell, the seat, the spindle, the gear wheel, the carrier gear, the upper top plate.

This consists of a water tank, a leak test shelf, an inlet for the barrel of star wheel gear, a discharge for the barrel of star wheel gear, an outlet for the barrel of star wheel, a transmission, a motor, a pneumatic motor component, and a conveyor chain.

Work principle:

A rotary leak machine with 12 workstations is used with water, electricity, and instrument Air. As a first step, the straight conveyor transported barrels into the barrels of star wheels. When the main engine is running, the solenoid valve of the leak test bench opens, the control cylinder pushes down the barrels of the leak test bench.

With the test shelf placed in the water tank and the air valve opened to inflate the barrel simultaneously, the air pressure is 0.6-0.8MPa, and cracked barrels or barrels with holes will bubble when they are immersed in the water fully after 1-2 seconds. With this method, the operations staff are able to easily spot bad barrels and remove the ones that are defective.

Technical parameter:

|

1 |

operating model |

Rotary |

|

2 |

leak test station |

12 stations, customized |

|

3 |

leak test speed |

2000 BPH |

|

4 |

leak test standard |

5 gallons barrel |

|

5 |

leak test precision |

0.05mm |

|

6 |

Barrel mouth diameter |

Φ55mm |

|

7 |

Barrel height |

490mm |

|

8 |

Barrel diameter |

Φ270mm |

|

9 |

Work pressure |

0.6-0.8MPa |

|

10 |

Leak test pressure |

0.08-0.12MPa |

|

11 |

Air consumption |

1.2-1.6m/min |

|

12 |

Water consumption |

432L Recycle |

|

13 |

Total motor power |

2KW |

|

14 |

Overall dimension |

Length2550×width2300mm ×height2500mm |

|

15 |

Weight |

3000kg |

|

16 |

Voltage |

380V |

Transportation:

Export standard packaging: wooden case

Port: Tianjin port or other assigned port

English

English Chinese

Chinese